Schmidt Associates Completes State’s First Post-Tension Concrete Track Design

-

Category

Studio-K12, Perspectives -

Posted By

Bob Ross -

Posted On

Jul 03, 2023

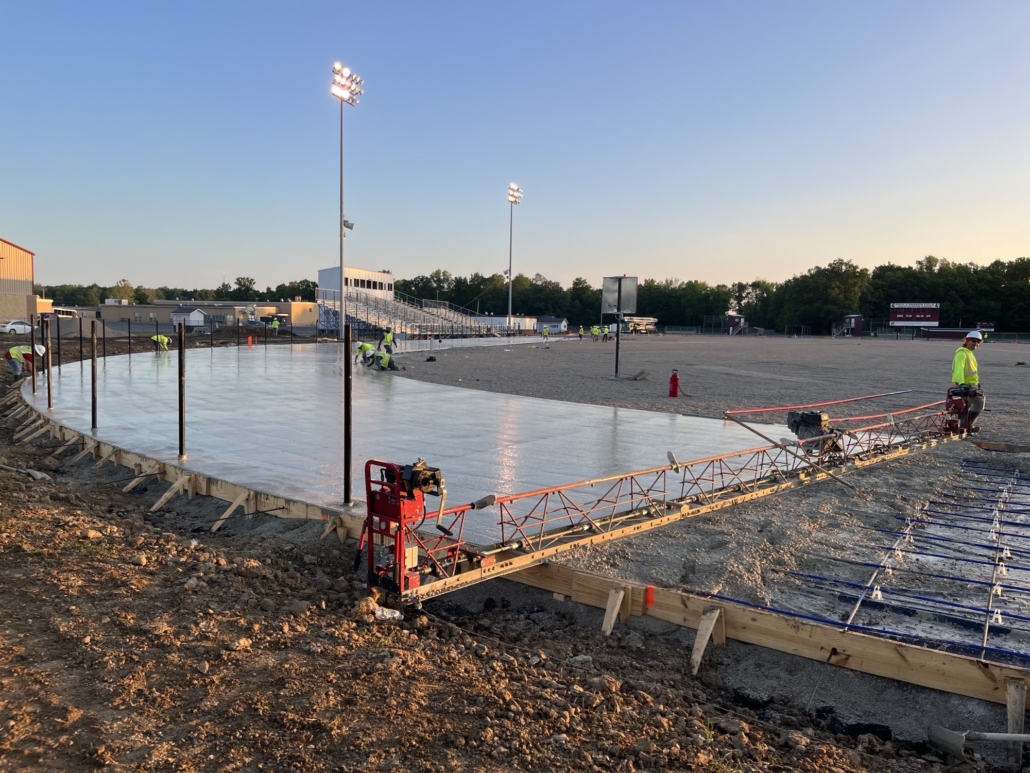

Post-tension concrete tracks are emerging as a new and beneficial design option for K-12 schools due to their durability and long-term use. Recently, our team of engineers worked with Wes-Del Community School Corporation to design and implement a post-tension concrete running track, the first track of its kind in Indiana. The new track, which was recently poured, will be substantially complete in time for the 2023-24 school year. In this blog post, we will explore what post-tension concrete tracks are, their advantages over traditional asphalt tracks, and how schools can get started with the design process.

A post-tension concrete running track is constructed by pouring concrete over cables or tendons that extend from one end to the other. This method provides the track with greater reinforcement compared to asphalt. As the concrete hardens, the cables are mechanically tightened, creating tension within the concrete. This process actively prevents large cracks that often occur with asphalt tracks.

The main reason why school districts should consider post-tension concrete tracks is their longevity. While asphalt tracks typically last around 10 to 15 years with proper maintenance, post-tension concrete tracks can have an average usage time of up to 25 years or longer, with resurfacing every five years. Unlike asphalt, which requires repairs before resurfacing, post-tension concrete tracks eliminate the need for costly repairs, saving both time and money.

The construction of post-tension concrete tracks has a relatively quick turnaround time. Once the decision is made to go with this option and the concrete is poured, it takes approximately 28 days to cure and harden before surfacing can be done. After resurfacing, a waiting period of seven days is necessary before the track can be used. Considering the time it takes to pour the concrete, complete the resurfacing, and the extended lifespan, post-tension concrete tracks offer great value.

The cost of post-tension concrete tracks varies depending on factors such as size and any necessary demolition or renovation of pre-existing tracks. While there may be an initial investment, the longer lifespan and reduced need for repairs make post-tension concrete tracks a cost-effective option in the long run.

In terms of user experience, there are no noticeable differences between asphalt and post-tension concrete tracks. However, the significant difference lies in the overall maintenance required. Post-tension concrete tracks require less maintenance, resulting in reduced costs and effort for school officials.

Another advantage of post-tension concrete tracks is their resistance to drainage or soil concerns. Unlike asphalt, which can crack, heave, or settle with changing temperatures, concrete tracks provide a stable and durable surface.

Consider the benefits of post-tension concrete tracks, such as their longevity, reduced maintenance, and resistance to soil and drainage issues. By choosing this innovative design option, schools can save money and provide students with a durable and high-quality athletic facility.

For years, Schmidt Associates has been designing post-tension concrete tennis courts as a viable and cost-effective option for school districts. If your school district is interested in exploring post-tension concrete track design, Schmidt Associates architects and engineers can provide expertise and insight. With their experience in designing post-tension concrete tennis courts and being the first firm to complete a post-tension concrete running track, they are well-equipped to guide schools through the process.

Like what you read? Let’s talk!