What is VRF?

-

Category

Innovation -

Posted By

Jim Walde -

Posted On

Sep 26, 2017

VRF (variable refrigerant flow) is a sophisticated HVAC technology.

Invented around 30 years ago, this is known as the “Rolls Royce” of air conditioning systems. The use of the VRF mechanical system can assist in achieving LEED certification for facilities. The basic elements of VRF systems are:

- Refrigerant liquid is used as the cooling/heating medium, as opposed to chilled water systems. Those chilled water systems use refrigerant to cool/heat the water circulated throughout.

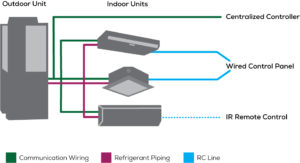

- Allows one outdoor condensing unit to be connected to multiple indoor evaporators. Each indoor evaporator is controllable by its user, varying the amount of refrigerant being sent to it and the speed of its evaporator fan.

- Inverter compressors allow lowering power consumption with partial cooling/heating loads.

- Ability to expand modularly, important when dealing with large projects.

Energy savings for these systems can be up to 55% over comparable unit systems. Ductwork sizes are reduced because conditioned air is not being routed throughout the building, which could also lead to smaller plenum spaces, and potentially reduce the height of the building if designed appropriately.

So how does it work?

A combination of surrounding outside temperatures and inputs from a user (desired temperature) gets calculated into the operation logic inside the system – resulting in optimal power consumption while outputting desired comfort temperatures. The basic steps of this:

- Indoor system is turned on by a user via the local remote.

- Outdoor system “gets noted” and will start up.

- Outdoor temperatures and desired indoor temperature point are examined within the system, the compressor’s output is then increased based on level of demand.

- The system then is constantly working to regulate power consumption based on demands of changing conditions (outdoor temperatures and user-desired temperatures).

Overall VRF has proven to be a highly efficient alternative to traditional 4-pipe HVAC systems, resulting in reduced installation and operational costs.